Your choices:

1 Biomass (solid); 2 Fuel: gaseous; 3 Electricity

| What is your resource? | What do you want to deliver? | What is the service the customer wants? |

| Biomass (digestible sludge) | District cooling | Comfortable indoor climate |

| Biomass (fermentable sludge) | District heating | 3 Electricity |

| 1 Biomass (solid) | Electricity | Process cooling (< 0 °C) |

| Geothermal | 2 Fuel: Gaseous | Process heat/steam (50 - 150 °C) |

| Sunshine | Fuel: Liquid | Process heat (150 - 1000 °C) |

| Water | Fuel: Solid | Process heat (> 1000 °C) |

| Wind | Local cooling (ind. house) | Transport |

| Residual oils/fats etc | Local heating (ind. house) |

Thermal gasification, integrated in a large-scale CHP or tri-production (heat, electricity and district cooling) plant opens up for an increase in the total electricity efficiency. The reason is that if the fuel is first gasified and the gas is then cleaned from ash components (the gas cleaning is still the bottleneck in this process concept), then a so-called "combined cycle" can be used for the electricity production. Plants based on this concept are usually denoted BIGCC-plants, Biomass Integrated Gasification Combined Cycle.

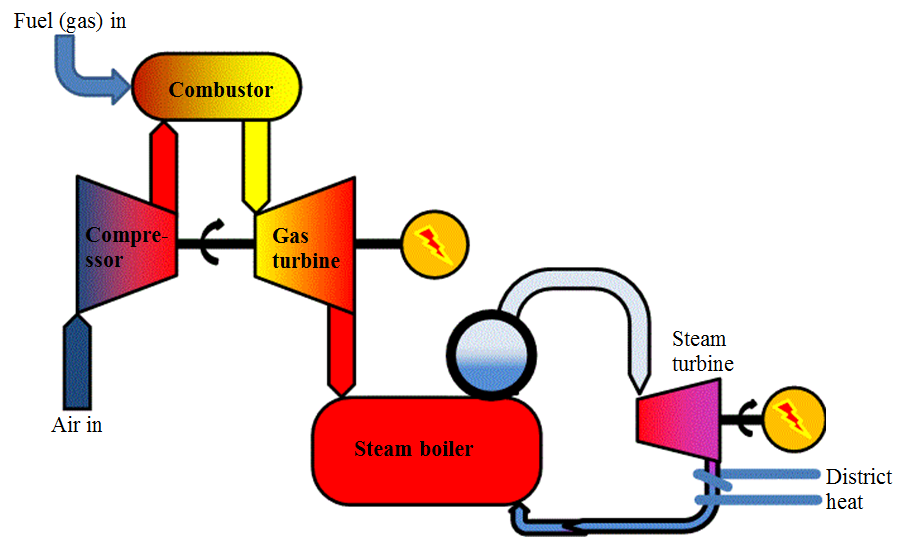

A combined cycle power production process makes use of the hot flue gases from the gas turbine to produce steam, uses the steam in a steam turbine and may finally produce district heating from the steam turbine outlet. The general schematic illustrates the process.

Gas turbines are very sensitive to deposition on and to erosion of the turbine blades and in the case of a gas turbine the blades are directly exposed to the flue gases from combustion. The fuel must therefore be free from ash and from such impurities that can form corrosive gases. Solid biomass, as well as sorted waste fractions or indeed any solid fuel are thus effectively excluded as gas-turbine fuels while clean converted fuels such as bio-methane, bioethanol or clean gasifier gas can well be used.

Though the gasification process in itself will induce energy losses and though the gas cleaning necessary to protect the gas turbine will also induce energy losses, the whole process may still be advantageous from an electricity efficiency point of view. However, to be feasible, this is only viable in large scale and has, so far (2013), not been demonstrated in commercial applications.