Your choices so far:

1 District cooling

| What is your resource? | What do you want to deliver? | What is the service the customer wants? |

| Biomass (digestible sludge) | 1 District cooling | Comfortable indoor climate |

| Biomass (fermentable sludge) | District heating | Electricity |

| Biomass (solid) | Electricity | Process cooling (< 0 °C) |

| Geothermal | Fuel: Gaseous | Process heat/steam (50 - 150 °C) |

| Sunshine | Fuel: Liquid | Process heat (150 - 1000 °C) |

| Water | Fuel: Solid | Process heat (> 1000 °C) |

| Wind | Local cooling (ind. house) | Transport |

| Residual oils/fats etc | Local heating (ind. house) |

With the current change in global climate, the global warming, the need for cooling during summers will increase and this holds true for single-family houses as well as for apartment houses and public buildings.

From a thermodynamic point of view, the production of low temperatures is complicated and requires exergy. The exergy can be supplied either as relatively small amounts of electricity in compressor cooling machines or via proportionally larger amounts of low-exergy energy carriers such as hot water in absorption cooling machines. From a system point of view, the supply of relatively smaller amounts of electricity may always seem the better alternative but in such cases when thermal energy is locally available close to the cooling/freezing needs, other solutions should be considered.

In the individual building, cooling can either be produced locally – even in single rooms – by electricity-consuming AC-units, (compressor heat pumps) or it may be achieved by means of a central cooling machine and be distributed as tempered ventilation air distributed through a forced ventilation system. The latter system is often used in office- and other public buildings while the first system is not un-common in older apartment buildings.

With increasing demands with respect to the indoor climate, forced ventilation and central air-conditioning units are successively installed in more and more buildings.

In such cases when a central heating/cooling air-conditioning unit is installed in a building and the tempered air is distributed through the building by a forced ventilation system, then the technical nature of the AC-unit can easily be changed from the electricity demanding compressor heat pump into a pair of heat exchangers.

The concept of district cooling is to distribute, through under-ground pipes, cold water to the individual buildings. The cold water is then used in a heat exchanger in the building, providing a cooling of the ventilation air and thus replacing the electricity demanding compressor heat pump (the AC-unit) by a plate heat exchanger. As the cold water passes through one building after another is will successively be warmed from its starting temperature (say 5 °C) to a level when it no longer useful for efficient cooling (say 15 °C) and it is then returned to the central cooling unit, cooled to 5 °C) and then circulated again.

As can be seen in the page treating district heating, the concept is identical – the difference being the temperature of the distributed water and that in district cooling the water is cooled in the energy plant – with district heating it is heated.

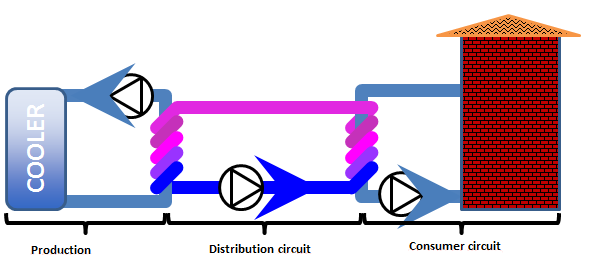

Thus, the system consists basically of three serial circuits, a production/cooling circuit, a distribution circuit and a customer circuit.

In a district cooling system, the core process is large-scale production of cold water. There are three major alternatives to do this:

- The first and cheapest alternative is to make use of naturally occurring cold water ("free cooling"). This may sometimes be the case: water at 4-6 °C) may be found at the bottom of nearby, sufficiently deep lakes or maybe as cold groundwater in the bedrock. Since this water will usually be saturated with oxygen it will need either to be pre-treated before distribution or it will, and this is the most common, be used in a primary loop to cool down the distributed water via a heat exchanger.

- The second alternative is to make use of compressor heat pumps – just like the common AC-units – to cool down the return water prior to re-distribution. Replacing a large number of small-scale compressor heat pumps cooling air with one large compressor heat pump cooling water will certainly improve the total system efficiency and reduce the total electricity demand for cooling but not as much as desired if the projections about increase cooling needs come out true.

- The third alternative – and the most attractive unless free cooling is available – is to integrate the production of cold water with the production of hot water and electricity and thus not only to save a significant amount of the electricity used for climate cooling but also to use the cooling need as a basis for new electricity production. This can all be achieved by the use of absorption heat pumps in a tri-generation plant. In absorption heat pumps the electricity-demanding compressor is replaced by an absorption-desorption circuit and the demand for electricity is radically reduced. The price paid is a need for large amounts of thermal energy but if the absorption heat pump is placed at a district heat producing plant, then, during summer when the cooling needs are big, there will be the possibility to produce vast amounts of such heat. At the same time – if the district heating plant is only big enough – electricity can be produced.

District cooling can thus be produced in district heating plants using solid biomass as their main resource. A district heating plant of sufficient size to host also electricity production would not have biogas or ethanol as the main fuel but it very well have integrated different energy sources such as waste combustion, solid biomass, biogas and solar energy and in such cases, these will also be the renewable resources used for district cooling production.

The whole thing may seem a bit like magic but let's work a simple example for a fictitious city:

- Assume there is a need of 10 MWh (10000 kWh) of climate cooling and this is provided through compressor cooling machines (AC-units). One may assume a cooling factor 2.5 which means that these AC units will need an input of 4000 kWh of electricity. With the European electricity mix, the total emission of greenhouse gases from electricity production amounts to approximately 6.75 kg of CO2 per kWh, so this will represent 27000 kg.

- Further assume that the same area has a total need of 10 MWh of electricity for cooking, illumination, electronics and such. This will then represent a total emission of 67500 kg CO2.

- Finally assume there is a need of 10 MWh of heat for tap- and hygiene water production and that this is produced locally in natural-gas fired heaters. Assuming the heaters to have 80% efficiency and the emission of CO2 from natural gas to be 0.275 kg of CO2/kWh one then finds a gas consumption equal to 12500 kWh and an emission 3438 kg, say 3500. The total greenhouse gas emission to supply this then becomes 98000 kg.

Now assume the very same needs but the production of three energy carriers – district cooling, electricity and district heating – takes place in a modern, biomass-fired tri-generation plant with a total efficiency 90% and an electricity efficiency 35%. Thus the efficiency for heat production becomes 55%. Finally: Biomass-firing is often assumed to have zero net emission of CO2 but this is a bit over-optimistic. For this example, 275 g/kWh biomass fuel energy is assumed. This is the same number as that used for natural gas firing in the above example and is considered a high value for biomass.

- To produce 10000 kWh (10 MWh) cooling capacity in absorption heat pumps one will have to supply first the double amount (20 MWh) of district heating water and then approximately 10% electricity (1 MWh or 1000 kWh). The district heating water is produced at 55% efficiency (90-35) so to provide 20 MWh to the heat pumps the fuel input needs be equal to 36400 kWh. But from this fuel we also get 35% electricity or a total of 12740 kWh! So when the heat for the heat pumps is produced, the side product in the form of electricity is already enough to run the heat pumps and the surplus, since the heat pumps needed 1000 kWh (1 MWh) amounts to 11740 kWh which is already more than the total amount of electricity demanded.

- Then there was a need for 10 MWh (10000 kWh) of heat and that is now produced at 55% efficiency. So the necessary fuel input becomes 18200 kWh of fuel. But at the same time, this fuel input will generate 35% electricity equal to 6350 kWh.

To sum up: 36.4 MWh of fuel energy is needed to provide the hot water to run the heat pumps and from that all the electricity needed is also obtained. Another 18.2 MWh of fuel energy is then needed to produce all the heat required. Adding up one finds a total of 54.6 MWh of fuel energy that needs be input corresponding to a CO2-emission of 15000 kg.

- Of the total fuel input 5500 kWh (10%) are lost since the total efficiency was 90%.

- 20000 kWh are used internally as hot water sent to the heat pumps to produce 10000 kWh cooling.

- 10000 kWh are delivered externally in the form of district heating.

- 1000 kWh of produced electricity are used internally to run the heat pumps.

- 18000 kWh (11740+6350) of electricity is produced and delivered to the grid.

The example illustrates how modern, biomass-fired tri-generation does not only reduce greenhouse gas emissions, from 98 tonnes to 15 in this example, but also opens up for an increase in electricity production (from 10 MWh delivered to 18 in this example) while providing at the same time climate cooling and comfort heating.

For the customer one main advantage with district cooling as compared to individual cooling is that the responsibility is handed over to a central, large-scale, production plant with 24-hour manning and professional personnel. Thus, the risk for breakages and the risk that the central AC-unit must suddenly be replaced at a high cost is minimised. The price paid is, of course, a fixed fee.

From an environmental point of view, the risk for brine leakages from one central heat pump maintained by professionals is much less than the risk for brine leakages from a large number of small AC-units, operated by laymen.

From a resource economy point of view, replacing electricity consumption for low-exergy energy services by delivery of a low-exergy energy carrier and electricity production is a step towards sustainability.

Biomass-fired tri-generation is already successfully installed in a number of Swedish cities and can be seen in full, commercial operation. Of course, the same reduction in greenhouse gas emissions would be reached if the tri-generation plant was natural-gas fired – but natural gas is not a renewable resource, so that option will not be long-term sustainable.